Innovations in Biochar Kiln Designs: Enhancing Efficiency and Reducing Emissions

Exploring cutting-edge kiln technologies that boost biochar production efficiency while minimizing environmental emissions.

The production of biochar—a carbon-rich material obtained through the pyrolysis of organic biomass—has seen significant technological advancements in kiln designs. These innovations aim to enhance production efficiency and reduce harmful emissions, aligning with environmental sustainability goals.

Emerging Kiln Technologies

- Kon-Tiki Flame Cap Kiln The Kon-Tiki kiln features a conical design that promotes efficient airflow, ensuring complete combustion and uniform heat distribution. This design minimizes emissions of harmful gases like methane and carbon monoxide, common in less efficient biochar production methods. Its simplicity and cost-effectiveness make it accessible for small-scale producers.

- Top-Lit Updraft (TLUD) Gasifier The TLUD gasifier is a micro-kiln that produces biochar and heat for cooking by pyrolyzing organic material. It utilizes a reburner to eliminate volatile byproducts, resulting in a cleaner combustion process. This design improves upon traditional methods by achieving smoke-free combustion and higher efficiency.

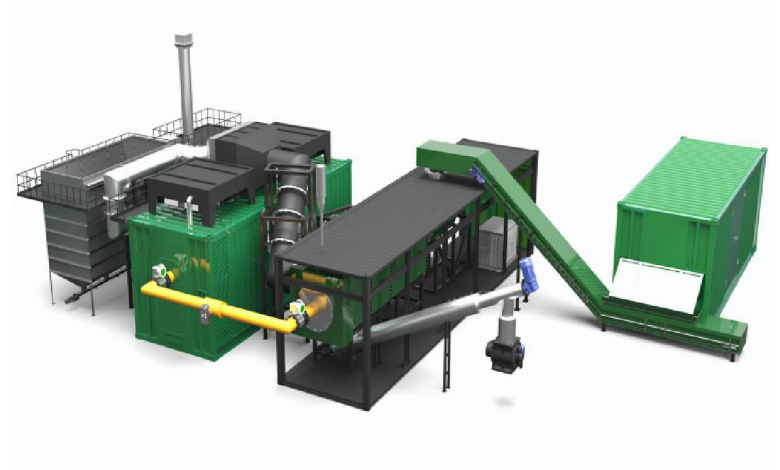

- Continuous Feed Pyrolyzers These systems allow for the continuous input of biomass, improving energy efficiency and reducing pollution emissions associated with batch kilns. They operate exothermically without air infiltration, enhancing biochar yields and enabling the recovery of co-products, thereby improving process economics.

- Nexus Biochar System Developed by Appalachian State University, the Nexus system integrates biochar production with solar thermal panels to heat water when the kiln is not in use. It also features efficient energy storage and a dehydrator for exhaust gases, exemplifying a holistic approach to sustainable energy and biochar production.

Efficiency and Emission Reductions

Innovative kiln designs have demonstrated significant improvements in efficiency and emission reductions:

- Energy Conversion Efficiency: Some biochar kilns have achieved energy conversion efficiencies of up to 47.02% and overall kiln efficiencies of 41.03% at steady-state operations over 500 °C.

- Emission Factors: Certain kilns have recorded methane emissions nearly at zero (<5.5 g/kg biochar) and carbon monoxide emissions between 21 and 82 g/kg biochar, indicating cleaner production processes.

Conclusion

Advancements in biochar kiln technologies are pivotal in enhancing production efficiency and reducing environmental emissions. These innovations contribute to more sustainable biochar production practices, supporting global efforts in carbon sequestration and soil health improvement.

Sources: