Decarbonising the Cement Industry with Biochar: A Carbon-Negative Solution for Sustainable Construction

The carbon intensive construction industry is poised for a green revolution with advancements in biochar and carbon-sequestering building materials. Ongoing research also highlights biochar’s potential to enhance concrete strength, paving the way for greener construction opportunities.

Together with its waste aversion benefits, which already reduce the amount of atmospheric CO₂ emissions released, biochar is being recognised as a replacement additive for cement.

What Is Biochar and Why It Matters…

Biochar is a stable, carbon-rich material produced through pyrolysis—the high-temperature decomposition of biomass in a low-oxygen environment. When manufactured at temperatures above 550°C, biochar contains a form of carbon structurally equivalent to inertinite, a highly stable component of the Earth’s crust, resistant to degradation.

This stability makes biochar ideal for durable carbon storage in construction materials. Metakaolin has shown promise in enhancing biochar cement quality further, improving the microstructure of the cement composition, increasing durability and overall concrete quality.

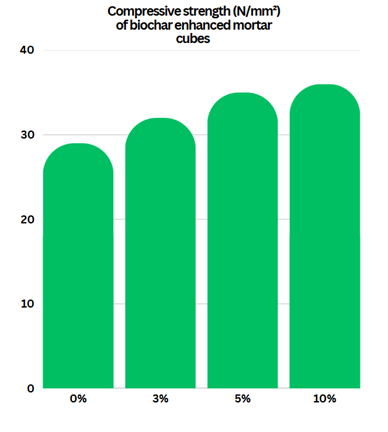

Biochar holds value not just in emission reduction, but also in improving the mechanical, thermal, and durability characteristics of concrete. The chart below indicates the improvements to compressive strength of biochar enhanced mortar, as a result of calcite and other hydration products which contribute to denser microstructure, in biochar added to cement composites:

https://link.springer.com/article/10.1186/s40712-024-00170-y#Fig7,

Carbon Sequestration Potential

Ensuring high quality biochar production will enable higher carbon sequestration opportunities, biochar produced from lower moisture level feedstock ensures a more efficient production process, with lower energy consumption, volatile emissions and higher biochar yields.

This expert table summarises the percentage CO₂ uptake of different biomass feedstocks used for biochar production:

| Types of Biochar | % CO₂ uptake |

| Wood sawdust | 5-6.5 |

| Unwashed hull of processed peanut | 5-7 |

| Mixed wood sawdust | 5.80-3.08 |

| Wood waste | 5.9 |

| Mixes woods | 2 |

| Peanut shell | 3 |

| Straw | 4 |

https://link.springer.com/article/10.1186/s40712-024-00170-y#Fig7,

According to the SpringerOpen Journal (2024), incorporating biochar into cement mixtures not only results in carbon-embedded building materials, but also ensures long-term sequestration due to the secure, inert environment of the concrete matrix. Once the concrete cures, usually within 28 days, the biochar is locked in, effectively removing atmospheric carbon for centuries. Even if the biochar infused concrete is recycled for other uses, the carbon will remain stable and will not be exposed. This makes biochar-concrete composites a certifiable method of permanent carbon removal.

Future Proofing the Cement Industry

Reducing reliance on traditional carbon emitters and revolutionising building materials, biochar offers us an optimised carbon strategy which combines carbon sequestration, waste aversion and value-added material benefits.

Research is ongoing into the abundant applications of biochar, with this in mind, any applications should be thoroughly researched and tested before use.