Biochar vs. Activated Charcoal: What’s the Difference?

Biochar and activated charcoal (activated carbon) are both forms of biobased, carbon-rich material made from organic matter. Although there is some overlap in application and source, they serve different purposes and have different properties due to how they’re produced and used. This article refers to activated charcoal throughout not charcoal (primarily used for fuel purposes).

Purpose and Application

Biochar

- Primary use: Soil amendment

- Function: Improves soil fertility, retains water and nutrients, sequesters carbon, and supports microbial life.

- Target user: Farmers, gardeners, environmentalists

Activated Charcoal

- Primary use: Filtration, adsorption, remediation and purification

- Function: Adsorbs toxins, odours, chemicals, and impurities in water, air, or the digestive system.

- Target user: Medical, industrial, and consumer use (e.g., water filters, gas masks, detox products)

Production Process

Biochar

- Produced via modern pyrolysis (heating organic biomass material—like wood, manure, or crop residues—in a low-oxygen environment)

- Typically made at lower temperatures (300–700°C)

- Less processed, with larger pore structure suitable for soils

- Negative emission technology

Activated Charcoal

- Starts with carbon-rich materials (biomass or coal etc.) and produced via pyrolysis, but undergoes activation (physical or chemical treatment to increase (micro)porosity and adsorption capacity)

- Made at higher temperatures (600–1200°C), often using steam or chemicals

- Highly processed to create a vast surface area (up to 3,000 m²/g)

Biochar Properties

- Lower surface area and porosity compared to activated charcoal

- Contains minerals and ash beneficial to soil

- Ion exchange capacity

- Longer-lasting in soil environments

Activated Charcoal

- Extremely high surface area and microporosity

- Optimized to adsorb gases, toxins, and chemicals

- Often inert, not designed to contribute nutrients

Cost and Availability

Biochar

- Generally cheaper, especially if made on-site

- Can be made from agricultural waste

Activated Charcoal

- More expensive due to the activation process

- Commercially refined for high performance

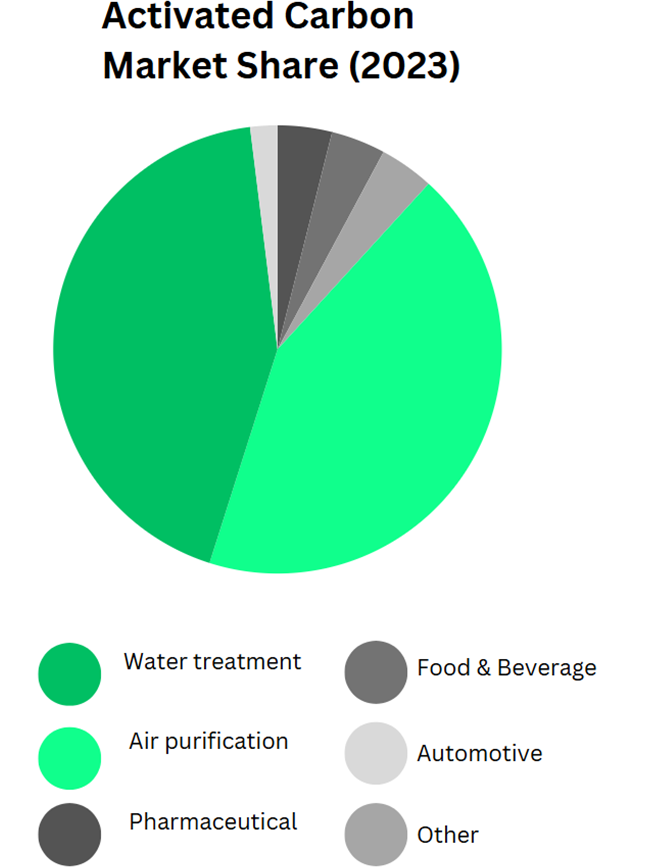

As global demand for water treatment and purification increases, with Clean Water Acts among many purification policies, the activated carbon market is expected to grow rapidly at a compound annual growth rate of approximately 9% in the next 4 years. Appointing the most suited carbon based material for the intended use remains paramount for successful application.