The Importance of Drying Biochar Feedstock Prior To Efficient Pyrolysis & Biochar Production

The production of biochar from woodchip feedstock has emerged as a promising strategy to enhance soil health, improve agricultural productivity, and contribute to sustainable environmental management. Central to optimizing biochar quality and its effectiveness when applied to soil is the integral step of drying the feedstock prior to pyrolysis.

Inputting moisture ridden biochar feedstock into the pyrolysis chamber for biochar production, fails to optimise the resource and causes unprecedented waste, not only of the feedstock but from the energy and labour required to produce the biochar.

Proper drying of woodchips/feedstock is not only central to the efficiency, biochar yield and consistency of the biochar production process but also directly affects the physical and chemical properties of the resulting biochar. Drying is a critical preparatory step, examining how moisture content impacts the thermal conversion process and, ultimately, the benefits biochar delivers when used as a soil amendment.

The benefits of drying feedstock before biochar production processes:

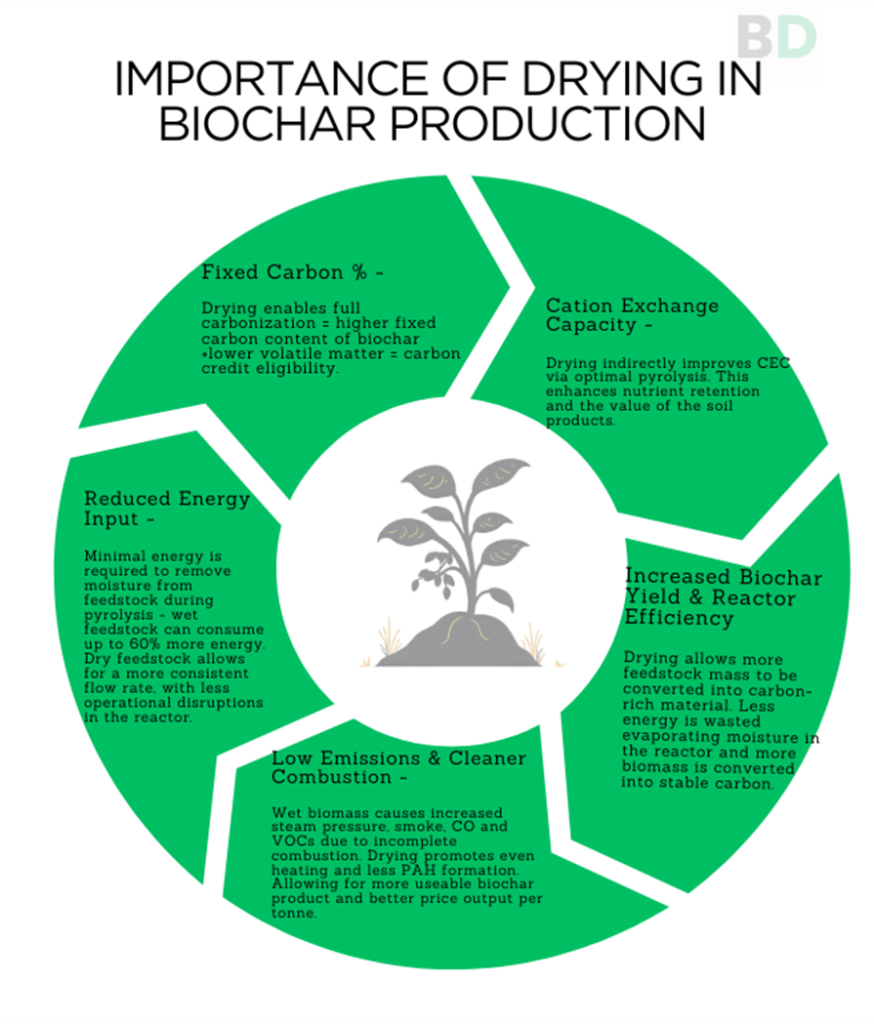

Energy efficiency  | Drying feedstock pre-pyrolysis significantly increases energy efficiency and allows for complete carbonization. Wet feedstock requires up to 2.5 MJ/kg of water just for evaporation. Pre-drying feedstock before input into the pyrolysis chamber reduces operating costs and residence times, allowing for higher temperatures at a quicker, more consistent rate. Drying optimises pyrolysis thermal efficiency, enabling the higher thermal output to be utilised for circular drying. |

| Higher Reactor Temperatures Achieved | Wetter feedstock absorbs heat energy and lowers the core temperature in the reactor. Inputting dry feedstock (>20%) allows for maintained optimal pyrolysis temperatures. |

| Dry Feedstock Reduces Emissions | Inputting dry feedstock into the pyrolysis chamber, greatly minimizes steam produced, VOCs and tars which all contribute to air pollution. By allowing for more complete carbonizations through moisture removal, the formation of methane, CO and other harmful greenhouse gases are reduced. |

| Enhanced Equipment Performance and Process Control | Pre-drying feedstock allows pyrolysis operators to have better control over temperature profiles and residence time. |

| Better Economic Viability | Investing in a suitable dryer is essential for better economic viability, increasing throughput and improving feedstock energy usage. Drying also extends the lifespan of biochar equipment. |

| Process Consistency and Control | Consistently low feedstock moisture content, below 20%, ensures uniform heating and consistent, high quality biochar yields. With minimal moisture in the feedstock, the risk of incomplete pyrolysis and equipment clogging is minimised. |

Container dryers like the one shown above serve as an excellent option for woodchip drying prior to pyrolysis and can often use residual waste heat from onsite pyrolysis processes to operate. Scaled to support suitable heat exchange equipment, your biochar dryer could form part of a circular onsite process. Speak to a suitable dryer adviser before purchasing.

Dry Feedstock Ensures Improved Biochar Quality and Product Consistency

High moisture content feedstock = low carbon content biochar.

Optimal dry feedstock allows for:

- Higher fixed carbon content and stability, ensuring effective long-term soil improvement and carbon sequestration.

- Increased biochar yield per unit mass of feedstock, allowing for improved carbon percentages in the final biochar output.

- Reduced energy input, dry feedstock uses less energy up during pyrolysis.

- Better biochar quality with a higher fixed carbon content, less moisture leads to more complete pyrolysis = higher fixed carbon content and lower volatile matter in the final product.

- Higher surface area and porosity, improves microbial colonization and nutrient retention. Improved porosity also improves water absorption rates in the soil.

The effect of drying on biochar profitability

Parameter | How Drying Affects This Parameter | Resulting Impact on Biochar Price and Revenue |

| Moisture Content (%) | Drying directly reduces moisture. | Dry feedstock= less weight, lower transport cost, better shelf life → higher net revenue per tonne of feedstock pyrolyzed. |

| Fixed Carbon (%) | Drying allows more complete pyrolysis → higher carbonization efficiency. | Higher fixed carbon = carbon credit eligibility + high-value soil markets. |

| Biochar Yield | Drying biomass before pyrolysis improves biochar yield by reducing energy loss to moisture evaporation. | This allows for more efficient carbonization of the feedstock. Increasing the biochar (kg) output significantly. |

| Volatile Matter (%) | Wet feedstock may quench pyrolysis → higher VM left. | Too much VM = low carbon permanence = lower price or rejection from carbon offset markets. |

| Contaminant-Free (Low PAHs, Heavy Metals) | Wet feedstock can cause uneven heating → formation of PAHs. Drying reduces this risk. | Cleaner char = certifiable, opens premium markets. |

| Ash Content (%) | Wet or improperly dried feedstock can lead to incomplete combustion or higher mineral volatilization → more ash. | High ash dilutes product value = lower price/tonne. |

| Surface Area (BET m²/g) | Dry feedstock enables more uniform pyrolysis and pore formation. | Higher surface area = value in filtration, water treatment. |

| Porosity | Indirect: better drying = better structural preservation of char. | Higher porosity = better microbial colonization, soil water retention, more valuable in premium agricultural markets. |

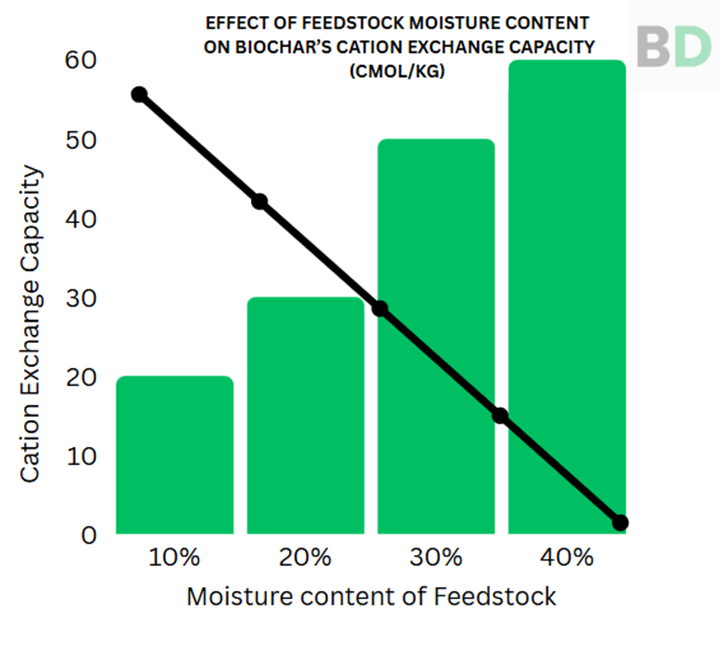

| CEC (Cation Exchange Capacity) | Enhanced indirectly by proper pyrolysis (which is enabled by good drying). | Better nutrient retention = higher price in soil blends and amendments. |